Minimum Order Quantities, or MOQs, can be very significant in wholesale ready to press heat transfers. Suppliers set MOQs to ensure cost efficiency, but they also create problems for businesses with changing needs. Knowing how to navigate MOQs can help businesses stay profitable and meet their production goals without overextending resources.

Understanding MOQs in Wholesale Ready to Press Heat Transfers

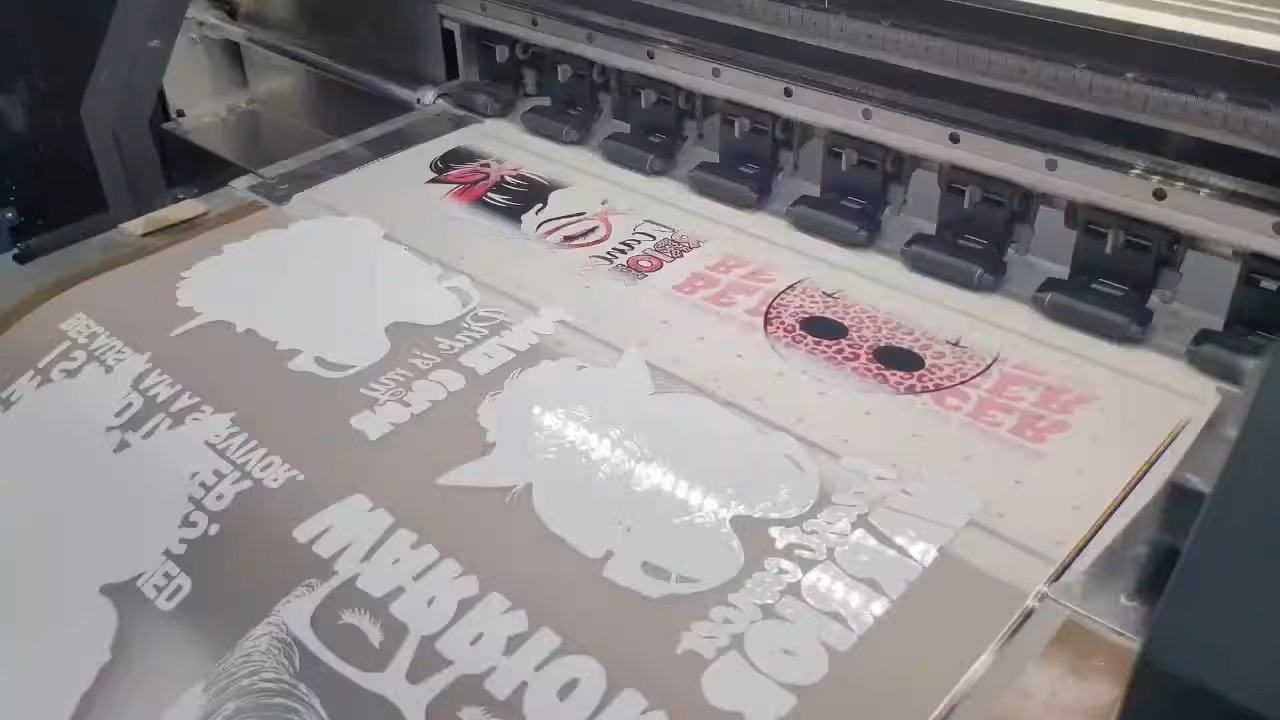

MOQs in the wholesale ready-to-press heat transfers market define the smallest quantity a supplier is willing to sell in a single order. These thresholds are typically set to cover production, storage, and logistics costs, ensuring suppliers can operate profitably. However, for buyers, meeting MOQs can sometimes strain budgets or exceed immediate needs, particularly for smaller businesses or those with niche markets. Suppliers often base MOQs on the production process, material costs, and market demand. For example, specialized heat transfers with custom designs or unique features may have higher MOQs due to their complex manufacturing process. On the other hand, standard designs may come with more flexible order quantities, offering businesses the opportunity to test products without committing to large volumes. Understanding these dynamics helps buyers assess whether the MOQ aligns with their business capacity and goals. Communication with wholesale ready to press heat transfers suppliers about specific needs and potential compromises can also open doors to more manageable arrangements.

Cost and Inventory of Wholesale Ready to Press Heat Transfers

One of the challenges companies face when buying wholesale ready-to-press heat transfers is balancing the MOQ with their actual inventory requirements. The larger the lot, the cheaper it generally is per unit; however, this also means more storage capacity and tied-up capital is required. Businesses that can’t maintain large MOQs because their demand might be inconsistent or storage capability is low are negatively impacted. To manage these challenges, businesses can focus on products with proven demand. Prioritizing top-selling designs or patterns ensures that inventory turnover remains steady, reducing the risk of surplus stock. Analyzing past sales data can guide businesses in selecting the right designs to meet MOQ requirements effectively. Another strategy involves collaborating with other businesses. Pooling resources with similar companies to meet an MOQ can be a cost-effective way to access wholesale ready-to-press heat transfers. This approach allows businesses to share the inventory burden while benefiting from reduced unit costs.

Negotiating with Wholesale Ready to Press Heat Transfers Suppliers

Navigating MOQs doesn’t always mean accepting the terms as they are. Many suppliers are open to negotiation, particularly when building long-term partnerships. Such possibilities for discussion with businesses can include lower MOQs for an initial order and phased deliveries. Suppliers can also offer tiered pricing, where smaller orders are slightly more expensive on a per-unit basis. This increases the price, but it gives businesses the option to test products before locking in larger orders. Demonstration of reliability and stable demand over time can also force suppliers to reconsider MOQ terms for future orders. Transparency in communication and a good relationship with suppliers help create win-win agreements. Trust between the two parties ensures smooth transactions and the possibility of customized solutions as business needs change.

Conclusion

Navigating MOQs for wholesale ready to press heat transfers requires strategic planning and open communication with suppliers. As businesses understand the reasoning for MOQs, bring into balance the need to maintain inventory, and find openings for negotiation, this issue becomes an opportunity for benefit. Proper management of MOQs not only brings forth cost efficiency but also serves to strengthen supplier relationships – the foundation for sustained growth within the competitive heat transfer market.